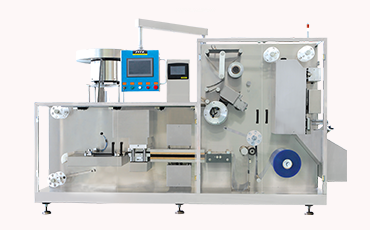

This machine adopt plate-type、positive pressure blow forming the blister, roller sealing with servo control system, insure the sealing and cutting can be transmited exactly. Also make it easy to operate、adjust、maintain and change the mould.

Performance Advantage

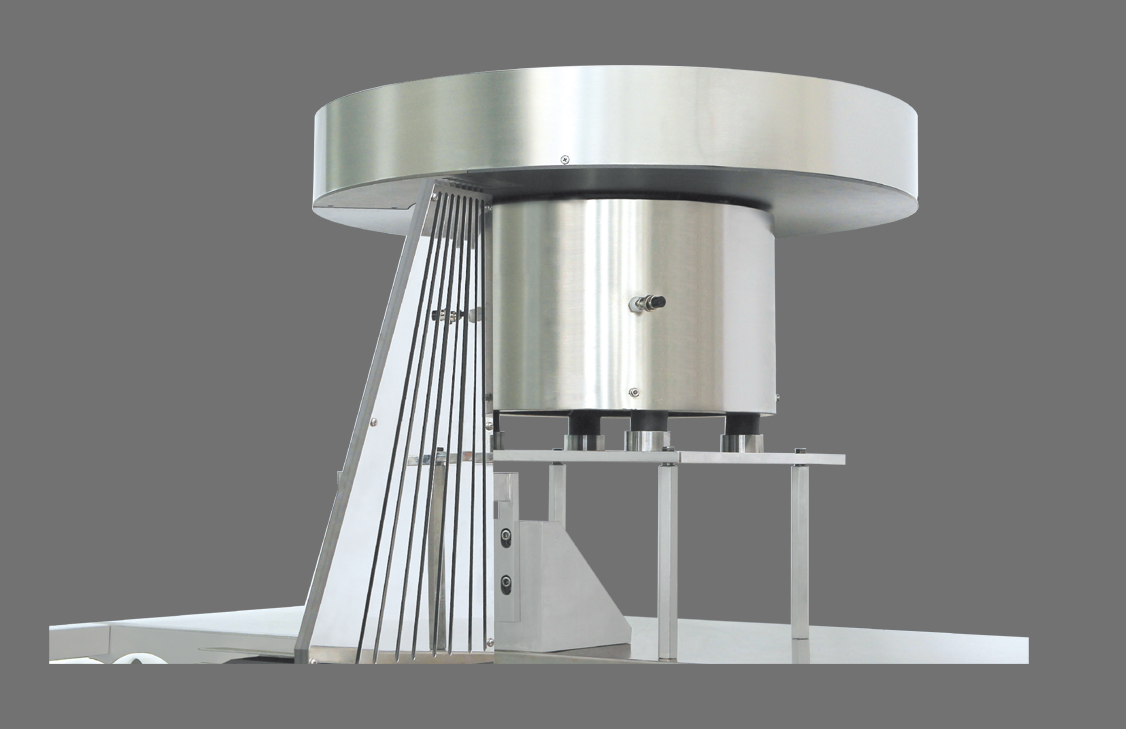

1.Six sets of independent servo motors used one the machine, make the machine run smoothly. Also it will make it easy to change and adjust the mould.

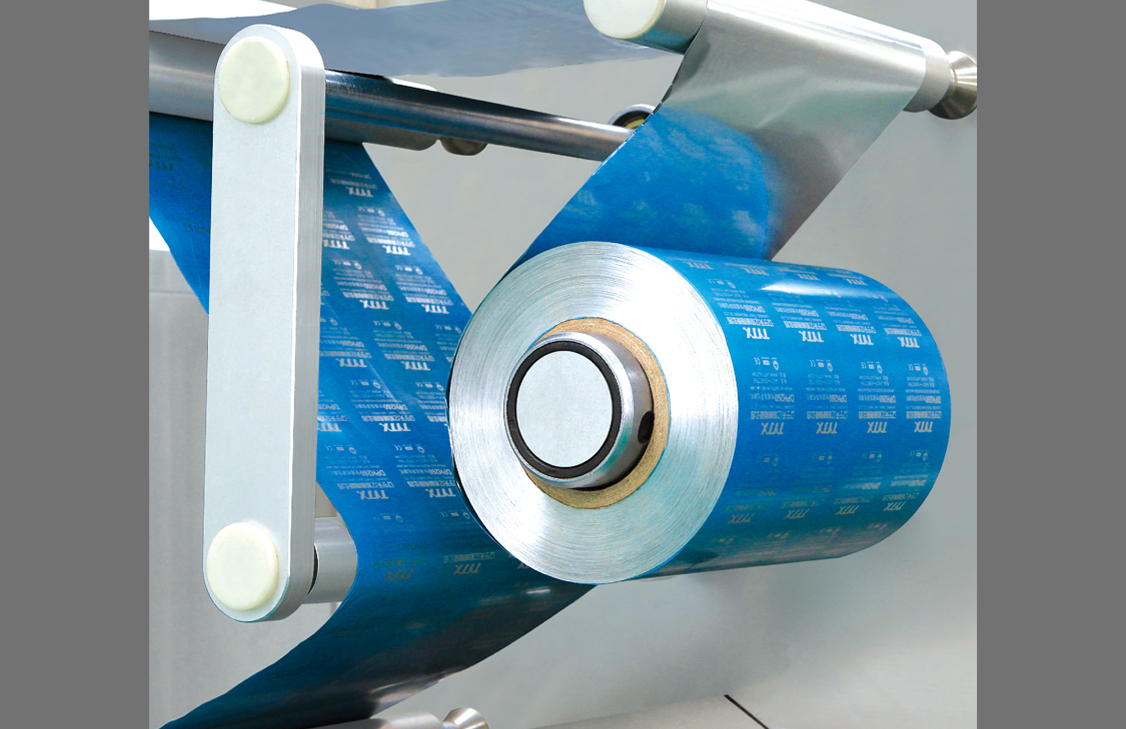

2.All work process like PVC heating 、PVC forming 、Printing、Printing batch number、cutting and so on, can be controled by HMI.

3.Large molding area, the size and shape of the plate can be arranged reasonable.

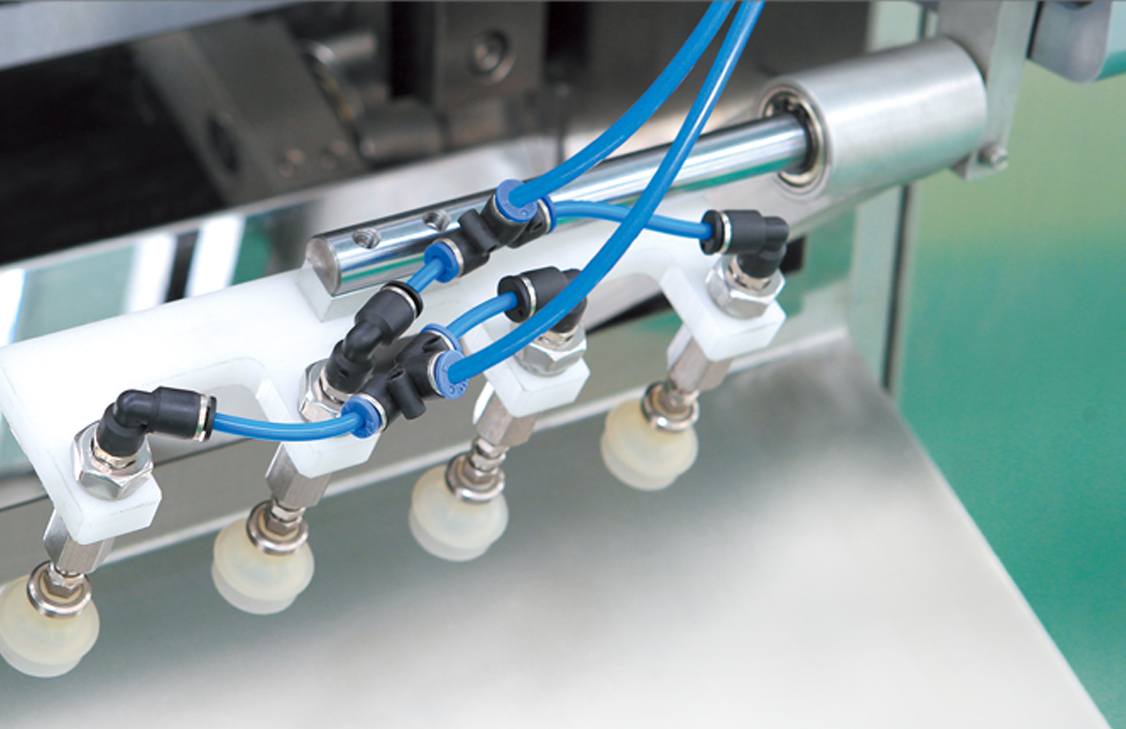

4.Vision system and rejection system can be choosed. With this the disqualification product will be rejected. The function of laser registration and servo control insure the plate transmited and cutted more accurate.