- Press Machine

- GZPTS700 SERIES SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

- GZPTS SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

- GZPTS-I SERIES SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

- GZPTS680 SERIES SERIES OF HIGH-SPEED DOUBLE SLIDE TABLET PRESS MACHINE

- GZPT SERIES SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

- GZPT-Y SERIES SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

- ZPT SERIES OF ROTARY TABLET PRESS MACHINE

- ZPTS SERIES OF ROTARY TABLET PRESS MACHINE

- Filling Machine

- NJP-8200D/6600D AUTOMATIC HARD CAPSULE FILLING MACHINE

- NJP-6000 AUTOMATIC CAPSULE FILLING MACHINE

- NJP-4500 AUTOMATIC HARD CAPSULE FILLING MACHINE

- NJP-3800 AUTOMATIC HARD CAPSULE FILLING MACHINE

- NJP-2200/3200 AUTOMATIC HARD CAPSULE FILLING MACHINE

- NJP-3200D AUTOMATIC HARD CAPSULE FILLING MACHINE

- NJP-1200 AUTOMATIC HARD CAPSULE FILLING MACHINE

- Packing Machine

- GHD-220 MULTI-FUNCTION HIGH-SPEED CARTONING MACHINE

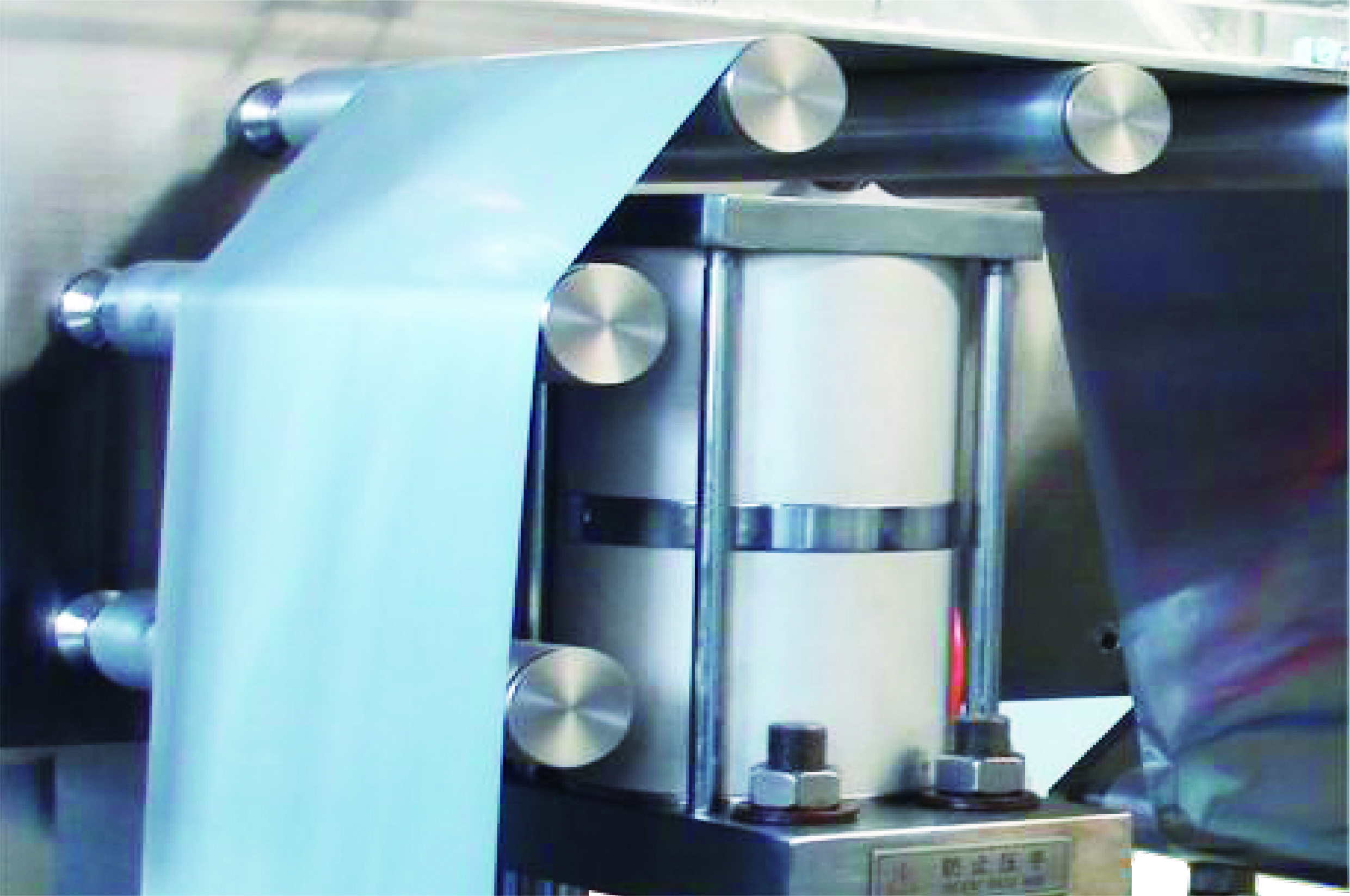

- DPH-280 ROLLER BOARD BLISTER PACKAGING MACHINE MACHINE

- DPH-280I ROLLER BOARD BLISTER PACKAGING MACHINE MACHINE

- DPP-260 PLATE TYPE PACKAGING MACHINE

- DPP-250 PLATE TYPE PACKAGING MACHINE

- DPH-260 HIGH-SPEED BLISTER PACKING MACHINE

- DXDK-900 GRANULE PACKAGING MACHINE

- DXDK-1200 GRANULE PACKAGING MACHINE

- PFS PLASTIC AMP FILLING AND SEALING PACKING MACHINE

- AUTOMATIC GRANULE PACKAGING INTELLIGENT ROBOT CARTONING MACHINE LINKAGE LINE

- BISTER PACKING AND CARTONING MACHINE LINKAGE LINE